Industrial bearings are often considered the unsung heroes of modern machinery. While they may not grab headlines like cutting-edge AI technologies or autonomous robots, their role in ensuring efficiency, reliability, and precision in industrial applications is nothing short of revolutionary. From manufacturing plants to wind turbines, bearings are a critical component in the machinery that powers industries worldwide.

In this blog, we will explore the pivotal role of industrial bearings in modern machinery, their types, and their contribution to revolutionizing industrial operations.

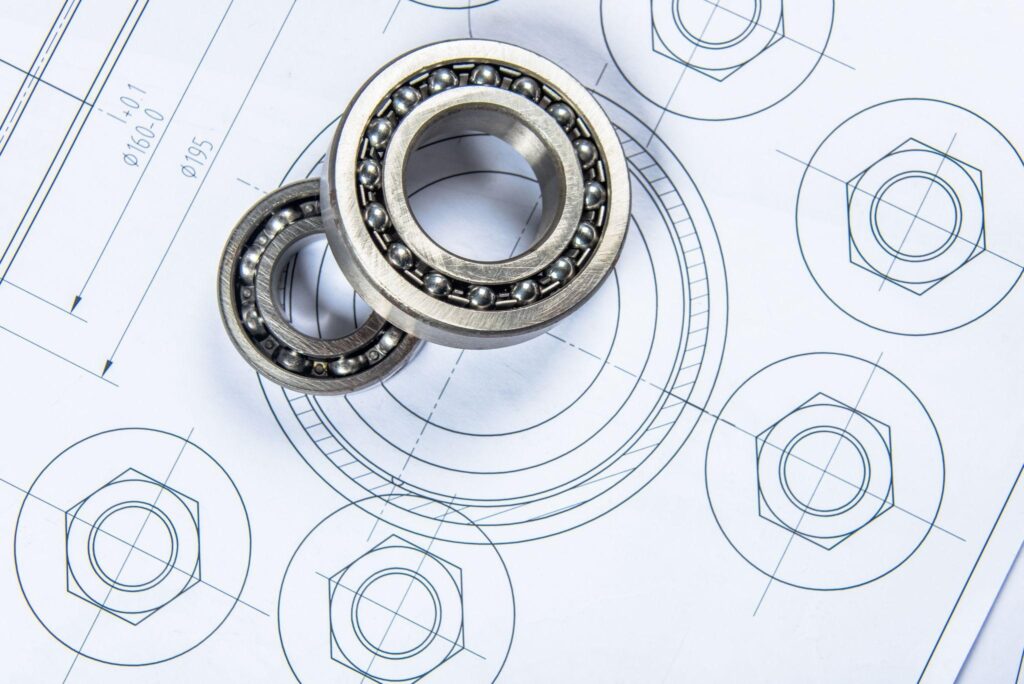

Industrial bearings are mechanical components that facilitate smooth and efficient motion between moving parts by reducing friction. They provide support for rotating or sliding shafts, enabling the transfer of power and minimizing wear and tear on machinery.

Understanding the various types of bearings is essential to appreciate their wide-ranging applications in modern machinery:

- Ball Bearings

- Used in applications requiring high-speed performance.

- Commonly found in fans, pumps, and electric motors.

- Roller Bearings

- Designed to handle heavy loads.

- Ideal for conveyor belts, crushers, and gearboxes.

- Tapered Roller Bearings

- Used in applications that involve combined radial and axial loads.

- Frequently used in automotive and heavy machinery industries.

- Needle Bearings

- Compact in size, suitable for tight spaces.

- Used in transmissions, steering systems, and aircraft applications.

- Spherical Bearings

- Allow angular misalignment and support heavy loads.

- Commonly found in wind turbines and industrial fans.

How Bearings Revolutionize Modern Machinery

1. Enhancing Efficiency

Bearings minimize friction, which translates to reduced energy consumption and improved operational efficiency. This efficiency is critical in industries such as manufacturing and power generation, where high productivity is essential.

2. Reducing Wear and Tear

By providing smooth motion, bearings protect machinery from excessive wear and tear. This prolongs the lifespan of equipment, saving industries significant costs in maintenance and replacement.

3. Supporting Heavy Loads

Industries like construction, mining, and automotive rely on bearings to handle extreme loads and harsh conditions. Specialized bearings ensure that these industries operate reliably without frequent breakdowns.

4. Enabling High-Speed Applications

From high-speed trains to electric motors, bearings allow machinery to operate at high speeds without compromising safety or efficiency. This capability has been instrumental in modern transportation and manufacturing advancements.

5. Facilitating Precision and Accuracy

In industries like aerospace, healthcare, and robotics, precision is non-negotiable. Bearings ensure accurate movements and positioning, enabling innovations in these critical fields.

Applications of Industrial Bearings

Industrial bearings are indispensable in various industries, including:

- Automotive: Bearings are used in engines, transmissions, and wheel assemblies.

- Energy: Wind turbines and hydroelectric plants rely on bearings for smooth operations.

- Manufacturing: Bearings play a key role in conveyor systems, robotic arms, and processing equipment.

- Aerospace: Aircraft engines and landing gear systems use high-performance bearings for safety and reliability.

The Future of Bearings in Modern Machinery

As industries adopt advanced technologies such as IoT, AI, and machine learning, bearings are evolving too. Smart bearings equipped with sensors can monitor their performance in real-time, predict failures, and optimize operations. This innovation aligns with the goals of Industry 4.0, where efficiency, reliability, and sustainability are prioritized.

Industrial bearings may be small components, but their impact on modern machinery is enormous. By reducing friction, enabling precision, and supporting high-speed and heavy-load applications, bearings are at the heart of industrial progress.

At Godavaritech, we take pride in offering a wide range of premium industrial bearings from globally renowned brands like Schaeffler (FAG & INA). With our technical expertise and customer-first approach, we ensure your machinery operates at peak performance. Whether you’re looking to enhance efficiency or extend the lifespan of your equipment, we’re here to help. Contact us today to explore the best industrial solutions for your business.