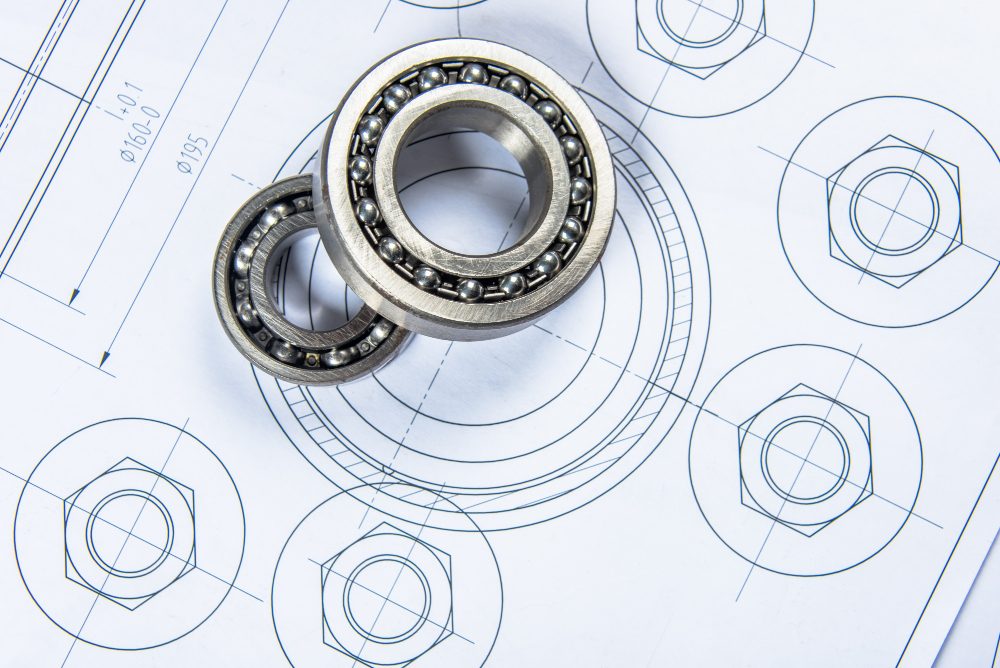

In today’s fast-moving industrial landscape, efficient machinery operation hinges on one often-overlooked component: bearings. These precision parts underpin rotation and mechanical motion in equipment across sectors from mining and cement to renewable energy and heavy manufacturing. However, their small size belies their massive impact: bearing failure is a leading cause of machine downtime, inefficiency, and unplanned maintenance costs.

Why Bearing Maintenance Matters

Preventing Unexpected Downtime

Industrial bearings are central to frictionless motion. Inadequate maintenance can lead to alignment issues, wear, corrosion, or failure each capable of shutting down production lines without warning. Routine inspections and lubrication checks help detect early anomalies like temperature rise, vibration, or noise, allowing for timely intervention before major breakdowns occur

Reducing Operational Costs

Unexpected failures and emergency replacements inflate operational expenses. A well‑executed preventive maintenance program, including cleaning, relubrication, and condition monitoring, cuts these costs significantly. It also improves energy efficiency and overall machine performance.

Enhancing Safety and Reliability

Malfunctioning bearings pose serious safety risks. Proper maintenance—supported with training, tools, and protective protocols—ensures equipment runs reliably and safely for operators and the entire plant

Advanced Solutions from Schaeffler

As the Biggest Schaeffler Bearings Distributor in India, Schaeffler offers a comprehensive suite of Bearing Maintenance Solutions that include mounting tools, remanufacturing services, lubrication systems, and onsite condition monitoring. These are part of the global Schaeffler Lifetime Solutions portfolio designed to keep machinery rolling longer and smoother.

Training & Tools: Schaeffler enables maintenance teams through advanced training programs so operations staff can perform diagnostics, mounting, and maintenance in-house.

Condition Monitoring: With vibration analysis, lubricant analysis, and infrared diagnostics, Schaeffler’s tools detect wear or emerging faults before failure occurs.

Remote Assistance: Their Virtual Fitter AR glasses help technicians install or inspect bearings remotely, reducing travel time and cutting service costs by nearly 50%.

Key Factors That Impact Bearing Life

The typical lifespan of rolling element bearings is affected by several factors: load conditions, operating temperature, alignment, contamination, lubrication quality, and handling during installation

Lubrication & Contamination Control

Using the correct lubricant, applied at proper intervals, is essential. Lubricant contamination from dust, moisture or debris dramatically reduces bearing life. Regular lubricant analysis and clean replacement cycles are critical.

Load & Thermal Conditions

Bearings operating under improper loads or at excessive temperatures are prone to fatigue, fretting, and early failure. Maintaining ideal operating environments and proper cooling helps avoid rapid degradation

Proper Installation & Alignment

Despite being small, incorrect mounting of bearings can lead to failure almost immediately. Up to 20% of bearing failures result from improper installation—easily prevented with the right tools and skill sets.

Industrial Impact Across Sectors

In heavy-duty industries like cement, mining or wind power, bearings must withstand extreme conditions. In wind turbines, for instance, the drivetrain and planetary gear bearings endure dynamic loads, temperature swings, and corrosive environments. Condition‑monitoring-enabled preventive maintenance can dramatically extend service life and reduce unplanned failures.

Conclusion

n the high-demand world of modern industry, where machinery performance directly influences productivity and profitability, bearing maintenance solutions play an irreplaceable role. From reducing unexpected downtimes to extending equipment life, proper maintenance ensures that businesses run efficiently and safely.Choosing the right partner is key — and that’s where Godavaritech, the Biggest Schaeffler Bearings Distributor in India, stands out. With deep domain expertise, a wide product portfolio, and a customer-first approach, Godavaritech empowers industries to optimize performance through reliable bearing solutions. Whether you’re looking for the most trusted Schaeffler distributors, or seeking long-term support for your equipment lifecycle, Godavaritech is the name industries trust.