In the fast-paced world of industrial engineering, efficiency and reliability are key drivers of success. Industries across the globe—from oil and gas to pharmaceuticals—are constantly seeking advanced technologies to optimize their processes. NETZSCH Pumps, renowned for their innovation and performance, are setting a new benchmark in industrial fluid handling. Let’s explore how these pumps are revolutionizing industrial processes.

Superior Efficiency Across Diverse Applications

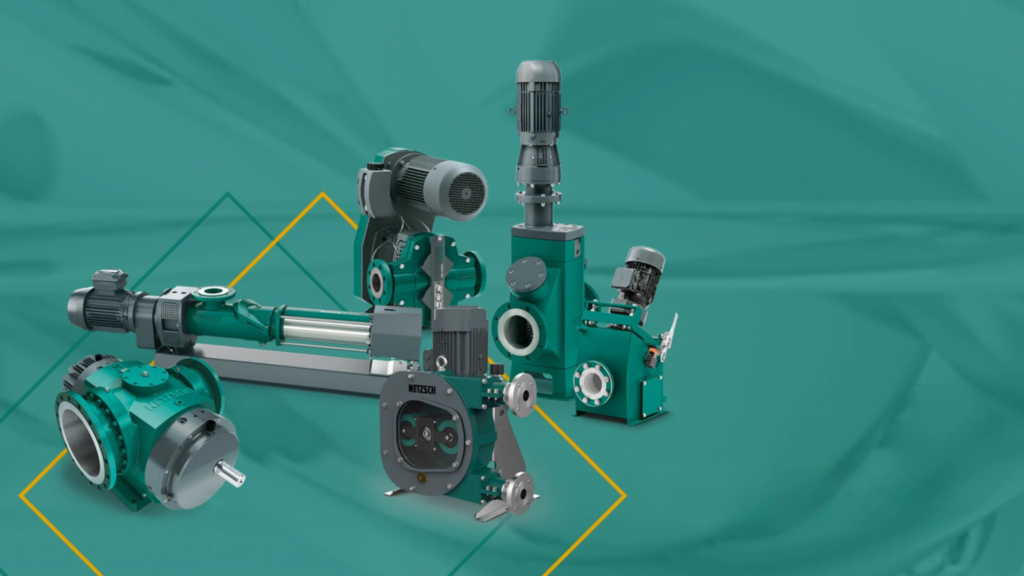

NETZSCH Pumps are designed to handle a variety of challenging applications, from transferring highly viscous materials to delicate, shear-sensitive fluids. Industries like wastewater treatment, food processing, and chemical manufacturing benefit immensely from their efficiency. By minimizing energy consumption and maximizing output, these pumps reduce operational costs while ensuring consistent performance.

Example: In the food industry, NETZSCH Pumps are used to handle ingredients like chocolate or yogurt with precision, ensuring no compromise on quality or texture.

Cutting-Edge Technology for Complex Needs

The innovative designs of NETZSCH Pumps, such as the NEMO® progressing cavity pump and the TORNADO® rotary lobe pump, cater to complex industrial needs. These pumps are engineered to provide:

- High suction capacity: Ideal for challenging applications.

- Customized solutions: Tailored designs for specific processes.

- Durability: Long service life even under demanding conditions.

Example: In the oil and gas sector, NETZSCH’s NEMO® pump handles crude oil with high sand content, ensuring smooth operations in abrasive environments.

Environmental Sustainability

NETZSCH is committed to promoting sustainability in industrial operations. Their pumps minimize waste, prevent leakage, and optimize energy usage. This aligns with the global push toward greener practices.

Example: In wastewater treatment plants, NETZSCH Pumps ensure efficient sludge processing, reducing environmental impact and supporting clean water initiatives.

Robust After-Sales Support

A key differentiator of NETZSCH is its dedication to customer satisfaction. With comprehensive after-sales support, including maintenance services and spare parts availability, industries can operate with minimal downtime and maximum reliability.

Example: NETZSCH’s global network ensures that clients in remote locations receive timely assistance, keeping their operations running smoothly.

Industry-Specific Customization

NETZSCH understands that each industry has unique challenges. Their range of pumps can be tailored to meet the specific requirements of various sectors, ensuring seamless integration into existing systems.

Example: In the pharmaceutical industry, NETZSCH Pumps are customized to maintain sterility and precision during the production of sensitive medications.

Why Choose NETZSCH Pumps?

When it comes to industrial fluid handling, NETZSCH Pumps are a class apart. Their cutting-edge technology, innovative designs, and robust construction make them the preferred choice across a wide range of industries. Here’s why NETZSCH Pumps stand out:

- Versatility Across Industries:

NETZSCH Pumps are designed to handle the most diverse applications—from highly viscous, abrasive fluids to delicate, shear-sensitive liquids. Whether it’s in oil and gas, pharmaceuticals, food and beverage, or wastewater treatment, NETZSCH Pumps deliver unmatched versatility.

- Proven Reliability:

In industrial processes, equipment failure can result in costly downtime. NETZSCH Pumps are built to last, even under the harshest conditions. Their wear-resistant materials and high-precision engineering ensure dependable performance, minimizing the risk of operational disruptions.

- Innovative Technology:

NETZSCH continuously pushes the boundaries of pump design, offering solutions like the NEMO® progressing cavity pump and the TORNADO® rotary lobe pump. These pumps provide features such as high suction capacity, self-priming capabilities, and seamless handling of difficult media, meeting even the most complex industrial requirements.

- Energy Efficiency:

With rising energy costs, efficiency is a top priority for industries. NETZSCH Pumps are designed to operate with minimal energy consumption, optimizing industrial processes while keeping operational costs low.

- Sustainability in Focus:

NETZSCH is committed to reducing environmental impact through innovative, eco-friendly designs. Their pumps help industries meet sustainability goals by minimizing waste, preventing leaks, and optimizing energy usage, thus promoting greener industrial practices.

- Tailored Solutions:

Every industry has unique needs, and NETZSCH understands this well. Their pumps can be customized to suit specific requirements, ensuring seamless integration into your operations. Whether it’s sterile pharmaceutical applications or abrasive fluids in mining, NETZSCH offers tailored solutions that meet your exact demands.

- Global Support Network:

NETZSCH’s extensive after-sales support ensures that industries worldwide can rely on timely maintenance, repairs, and spare parts. Their global presence means that help is always close at hand, regardless of your location.

Conclusion

NETZSCH Pumps are not just a tool for fluid handling—they’re a comprehensive solution that transforms industrial operations. With their innovative technology, energy efficiency, and robust performance, NETZSCH Pumps empowers businesses to optimize processes, enhance productivity, and achieve sustainability goals.

At GodavariTech, we are proud to be your trusted partner in bringing NETZSCH Pumps and other cutting-edge industrial solutions to your business. With over 45 years of expertise in industrial distribution, GodavariTech ensures seamless access to world-class products like NETZSCH Pumps, along with unparalleled customer service, technical support, and industry knowledge.

Discover how NETZSCH Pumps, in collaboration with GodavariTech, can revolutionize your industrial processes. Contact us today and let’s drive innovation and efficiency together.

Explore our range of solutions at GodavariTech’s official website. Together, we are redefining industrial excellence.