Industrial environments are rarely forgiving. Steel mills operate under extreme heat, cement plants battle constant dust, mining operations face shock loads and moisture, and heavy manufacturing lines run continuously under high stress. In such conditions, even a small component failure can bring production to a halt.

Downtime in harsh environments is not just inconvenient- it is expensive. Unexpected equipment failures lead to lost output, emergency maintenance, safety risks, and long recovery times. The challenge for industries is clear: how to maintain reliability when operating conditions are at their toughest.

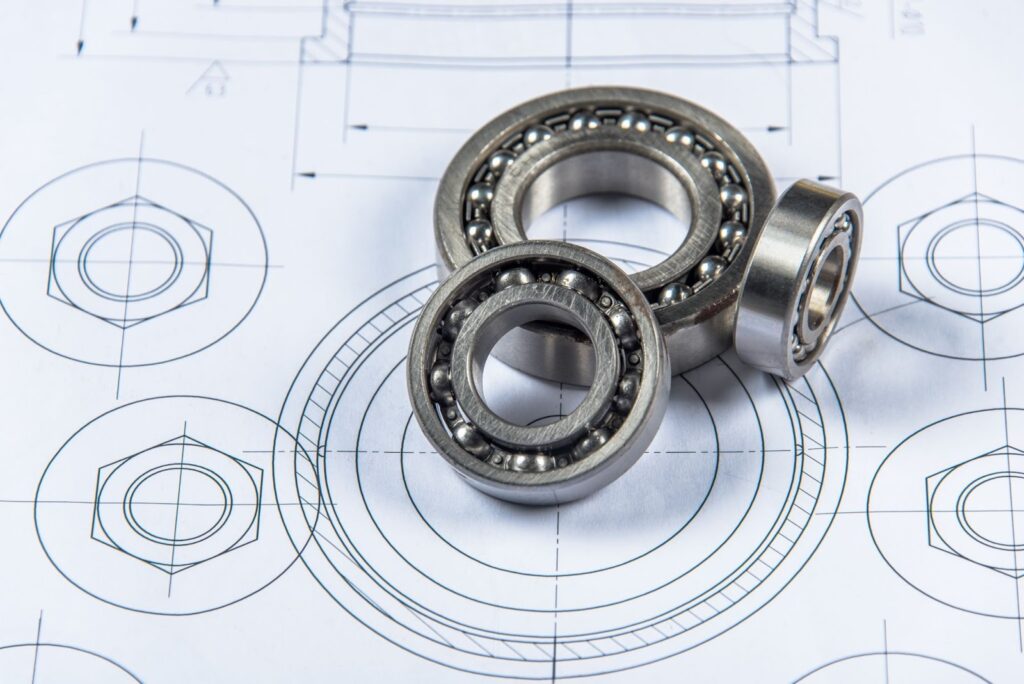

This is where Schaeffler’s advanced bearing and monitoring solutions play a critical role. By combining robust bearing engineering with intelligent condition monitoring, Schaeffler enables industries to reduce downtime, improve asset life, and maintain stable operations even in the harshest conditions.

The Problem: Why Harsh Environments Cause Frequent Downtime

Across heavy industries, the same reliability issues repeat themselves:

1. Accelerated Bearing Wear

Dust, slurry, moisture, and scale enter bearing housings, degrading lubrication and increasing friction.

2. Extreme Loads and Shock

Mining crushers, rolling mills, and kilns experience continuous heavy loads and sudden impacts that push components beyond standard limits.

3. High Operating Temperatures

Heat weakens lubricants and materials, shortening bearing life and increasing failure risk.

4. Limited Visibility into Equipment Health

Manual inspections are difficult, unsafe, or infrequent in harsh zones, allowing damage to progress unnoticed.

5. Reactive Maintenance Cycles

Without early warnings, maintenance teams respond after failure- resulting in long stoppages and higher repair costs.

These challenges make traditional maintenance strategies ineffective in harsh operating environments.

The Solution: Schaeffler’s Integrated Approach to Reliability

Schaeffler Industrial Solutions addresses harsh-environment downtime through a combination of advanced bearing technology and digital condition monitoring. This integrated approach helps industries move from reactive repairs to predictive, reliability-focused maintenance.

1. Bearings Engineered for Harsh Conditions

Schaeffler bearings are specifically designed to withstand:

- Heavy radial and axial loads

- Continuous vibration and shock

- High temperatures

- Contaminated and corrosive environments

Advanced materials, optimized internal geometry, and specialized heat treatments extend fatigue life and reduce premature failure. These design strengths make Schaeffler India products suitable for steel, cement, mining, and heavy engineering applications.

2. Advanced Sealing and Surface Technologies

In harsh environments, contamination is the enemy of reliability. Schaeffler integrates:

- High-performance sealing systems

- Wear-resistant raceway surfaces

- Corrosion-resistant materials

These features protect bearings from dust and moisture ingress, significantly reducing wear and lubricant degradation.

3. Digital Condition Monitoring for Early Fault Detection

Bearings rarely fail suddenly- they give warning signs first. Schaeffler’s monitoring solutions continuously track:

- Vibration trends

- Temperature changes

- Load variations

- Lubrication condition

These systems detect early-stage damage long before failure occurs, allowing maintenance teams to plan interventions during scheduled shutdowns.

This capability is a key part of Schaeffler Industrial Solutions, enabling reliable operations even where manual inspections are impractical.

4. Predictive Insights Instead of Emergency Repairs

By analyzing real-time data, Schaeffler’s monitoring technologies help identify:

- Misalignment and imbalance

- Lubrication starvation

- Bearing fatigue development

- Structural stress issues

Maintenance teams can then act proactively- reducing emergency stoppages and extending equipment life.

Real-World Impact Across Harsh Industries

Steel Plants

Advanced bearings and monitoring systems reduce unexpected failures in rolling mills and continuous casting machines, where downtime costs are extremely high.

Cement Manufacturing

Dust-resistant bearings combined with condition monitoring improve reliability in kilns, crushers, and fans operating at high temperatures.

Mining Operations

Shock-load-resistant bearings and remote monitoring protect crushers, conveyors, and screens located in difficult-to-access areas.

Power & Heavy Engineering

Early fault detection prevents catastrophic damage to rotating equipment, improving plant availability and safety.

Across these applications, Schaeffler Group products help industries maintain productivity despite harsh operating conditions.

Why Authorized Schaeffler Partners Matter

Advanced bearing and monitoring solutions must be selected and installed correctly to deliver results. Working with an Authorized Distributor for Schaeffler ensures:

- Genuine Schaeffler products and technologies

- Application-specific bearing selection

- Proper integration of monitoring systems

- Access to the complete Schaeffler Industrial Solutions portfolio

- Long-term technical support

This is why manufacturers rely on experienced Schaeffler distributors in India instead of fragmented sourcing.

How Godavaritech Supports Downtime Reduction

As a trusted Schaeffler authorized partner in India and one of the Biggest Schaeffler Bearings Distributor in India, Godavaritech helps industries tackle downtime in harsh environments with confidence.

Godavaritech supports customers through:

- Supply of genuine Schaeffler bearings and monitoring solutions

- Expertise as a Schaeffler Bearing Supplier and Dealer of Schaeffler Bearings

- Guidance on selecting solutions for extreme operating conditions

- On-ground technical and after-sales support

- Reliable access to products through established Schaeffler India distributors

By combining Schaeffler’s engineering excellence with local expertise, Godavaritech enables industries to reduce downtime, extend equipment life, and improve operational resilience.

Conclusion

Downtime in harsh industrial environments is not unavoidable- it is often the result of inadequate component design and limited visibility into equipment health. With Schaeffler’s advanced bearing and monitoring solutions, industries gain the strength, intelligence, and predictability needed to operate reliably under extreme conditions.

Supported by Godavaritech as a leading Schaeffler Bearings distributor, manufacturers can move beyond reactive maintenance and build a robust reliability strategy that keeps operations running- even when conditions are at their toughest.